INSTANT ON NOW AVAILABLE - Experience Time to first frame as quick as 2 SECONDS

How Utility Leaders Can Capture Value from Digital Twin Technology

Customer data is valuable to businesses in nearly every industry, and utilities are no exception. By tracking where, when, and how customers use resources like electricity and water, utilities can streamline operations and deliver energy more efficiently. The advent of 5G technology is creating even more opportunities for optimization. Streetlights equipped with 5G-enabled IoT sensors, for instance, can be turned on automatically based on the amount of pedestrian traffic or sunlight in a given area, using electricity only when it’s needed.

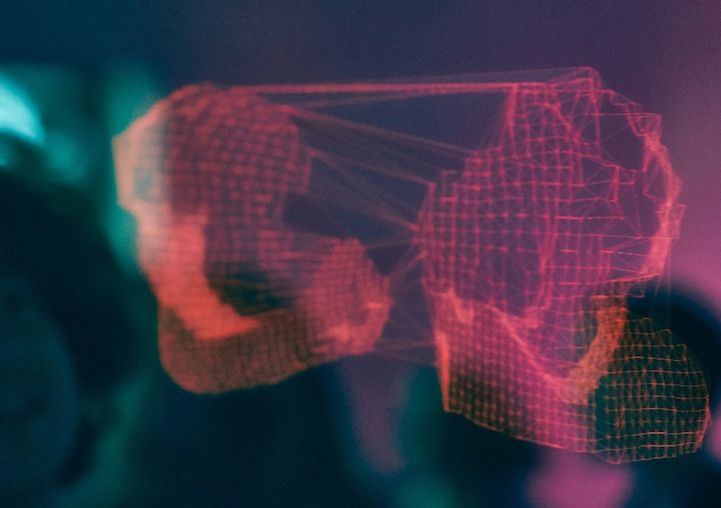

With digital twin technology, utilities can create an easily accessible digital representation of their physical energy-delivery systems — including smart sensors and other connected assets, which might be spread across entire cities or regions. This allows them to not only track the real-time performance of these assets, but also to create simulations demonstrating how they will perform in virtually any future scenario.

The opportunities for energy companies to implement digital twin technologies are endless, but capitalizing on them requires data that’s not always available. Like many enterprises in other industries, utilities rely on a vast network of disconnected applications and technologies. Data being generated by CAD or BIM software, IoT devices, GIS platforms, and the countless other assets these companies rely on is rarely stored in a unified way. In order to create authentic digital twins that truly mirror real-world energy systems, utilities must establish the right standards for interoperability.

It’s a tall order for any organization, but for utility companies especially, it’s a goal worth pursuing.

Unlocking Value Across the Enterprise

A comprehensive digital twin that incorporates data from across a utility’s information technology (IT) and operational technology (OT) infrastructure can make the entire organization smarter and more efficient. The physical assets that energy companies depend on are often technically complex, even dangerous. With a complete 3D representation of, say, a nuclear reactor, a company can conduct performance assessments from anywhere on any device and refrain from sending personnel to the site until an issue has been diagnosed. There are also important implications for employee development.

- Training is critical for the personnel tasked with managing or maintaining a utility’s physical assets. It can also be expensive. Sending an employee (or many employees) halfway across the country to learn about drilling equipment or to renew a line technician certification costs both time and money. Since a digital twin replicates a physical asset down to the finest detail, employees can view it just as they would in the real world without leaving their home or office. Moreover, the experiential training programs that can be created using digital twins can facilitate greater knowledge retention as compared to traditional online or onsite programs.

Read Next: How companies can deliver 3D training simulations to any mobile device

If you’re leading a modern utility, you can probably imagine the potential for cost savings, risk mitigation, and employee development accompanying this technology. While you might still be working toward organization-wide interoperability, you can probably already build useful digital twins replicating some of your most important assets. Here’s how:

1. Identify the data you’ll need

As its name suggests, a digital twin is an identical virtual replica of a physical asset. That means the same data sources feeding the real-world asset must be integrated to create its digital counterpart. Before beginning development, your team might need to break down internal sources into more granular integrations and be able to access or replicate relevant external data sources.

2. Focus on the front end

Users will access your digital twin via a web or mobile application. Alternatively, an interactive 3D streaming solution like PureWeb's will provide access via a secure URL. In either case, you’ll need to ensure that the physical attributes of the real-world asset being replicated are effectively captured onscreen using real-time data to reflect changes as they happen. For systems affected by external conditions, you’ll want to ensure that your 3D rendering captures relevant features of the surrounding environment as well.

3. Introduce disruption

Once you’ve built and validated a baseline model, you can begin simulating potential scenarios. Your team should decide which prescriptive algorithms to incorporate based on the real business problems you want to solve. You’ll then begin testing these by introducing model disruptions, which could reflect meteorological, financial, physical, or social disruptions that could impact your physical asset.

4. Facilitate usage

In order to derive real value from a digital twin, it must be accessible to users on demand. To facilitate that access, you’ll need a solution that can process incoming data in real-time and render the data in a format that is understandable by employees across departments. The most intuitive format is a digital visualization. Moreover, you’ll want to be sure that users can interact with your 3D environment in a way that’s intuitive and effectively imitates real-world interaction.

Related Read: How to achieve data interoperability with 3D visualizations for your digital twin

PureWeb helps clients through every stage of digital twin development. With our unique proprietary technology, we can connect multiple disparate applications into one seamless user experience. If you don't yet have interactive 3D assets built, we can connect you with appropriate professionals within our ecosystem of 3D content creation agencies and studios. Using the PureWeb Platform SDKs, you can connect your interactive 3D visualization to a wide range of data sources, services, and applications. The result is a digital twin that enables more efficient user workflows and greater collaboration across multidisciplinary teams.